Case Studies of EXTEND3D

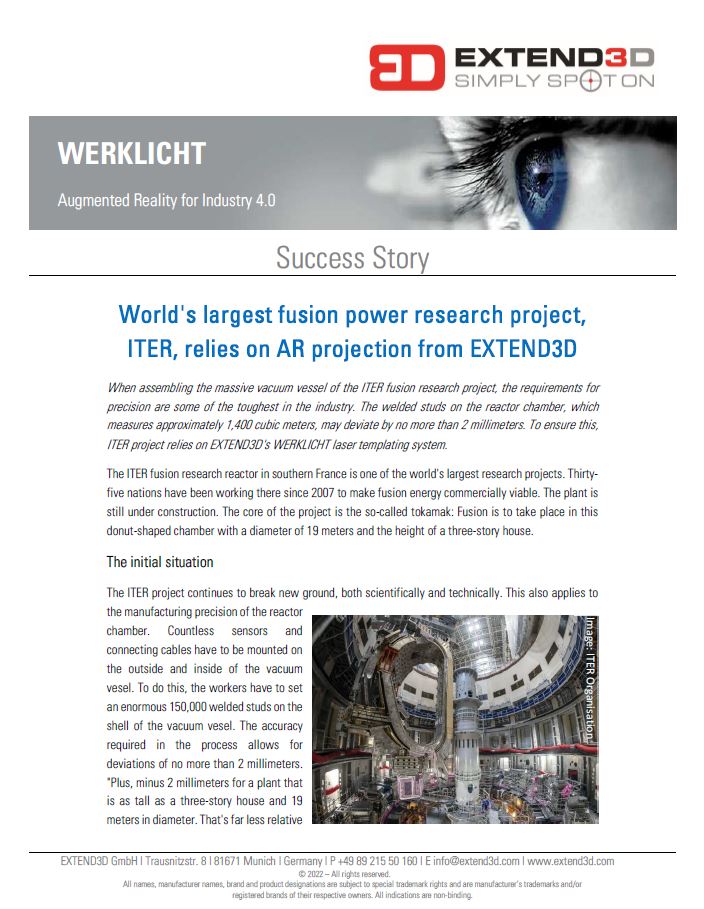

When assembling the massive vacuum vessel of the ITER fusion research project, the requirements for precision are some of the toughest in the industry. The welded studs on the reactor chamber, which measures approximately 1,400 cubic meters, may deviate by no more than 2 millimeters. To ensure this, ITER project relies on EXTEND3D’s WERKLICHT laser templating system.

Few areas of the manufacturing industry are as complicated as special vehicle construction. Vehicles such as government vehicles, stretch limousines and armored vehicles are highly specialized one-offs – often produced in batch size 1, which makes automation difficult. To meet these challenges, the special vehicle manufacturer IndiKar now relies on the WERKLICHT laser assistance system from EXTEND3D.

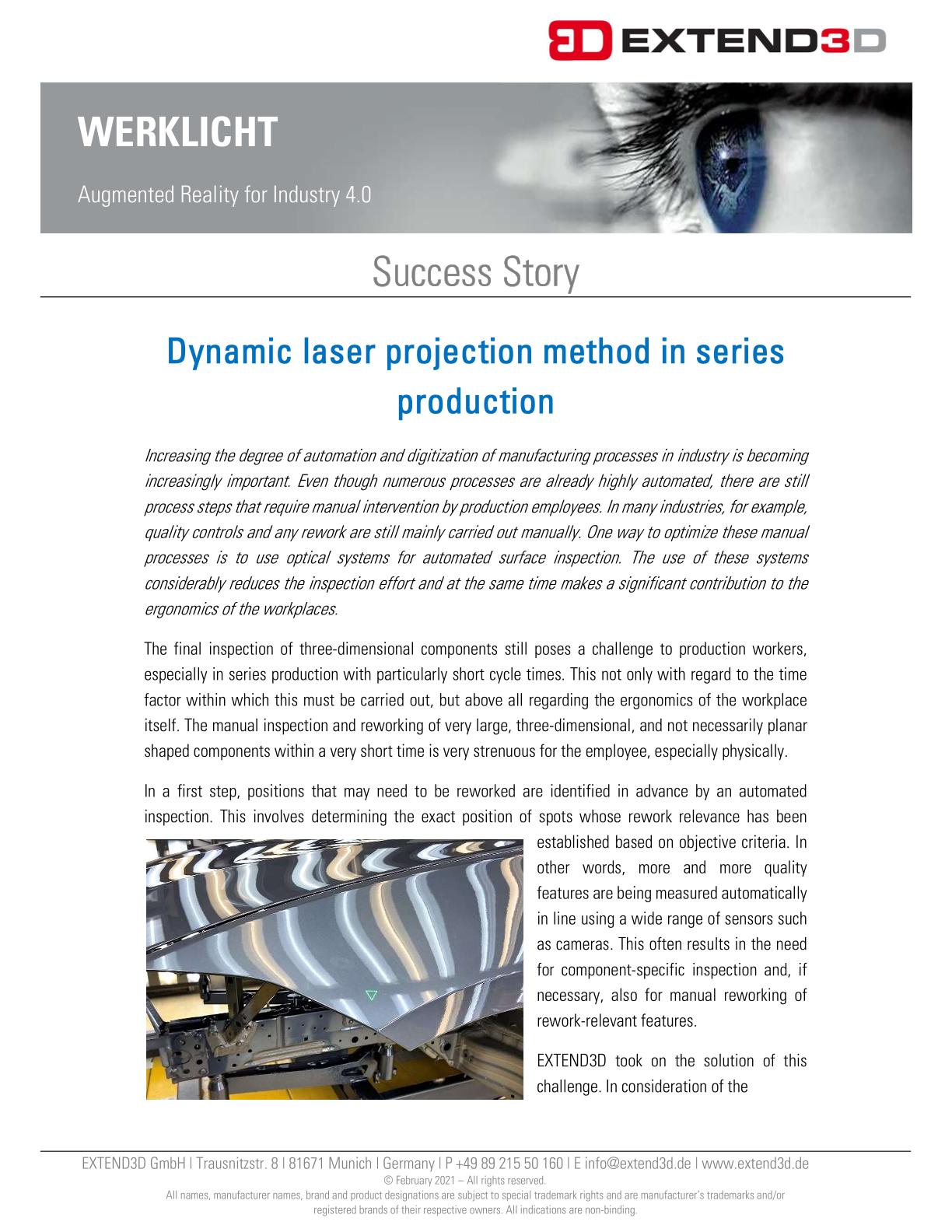

Increasing the degree of automation and digitization of manufacturing processes in industry is becoming increasingly important. Even though numerous processes are already highly automated, there are still process steps that require manual intervention by production employees. In many industries, for example, quality controls and any rework are still mainly carried out manually. One way to optimize these manual processes is to use optical systems for automated surface inspection. The use of these systems considerably reduces the inspection effort and at the same time makes a significant contribution to the ergonomics of the workplaces. …

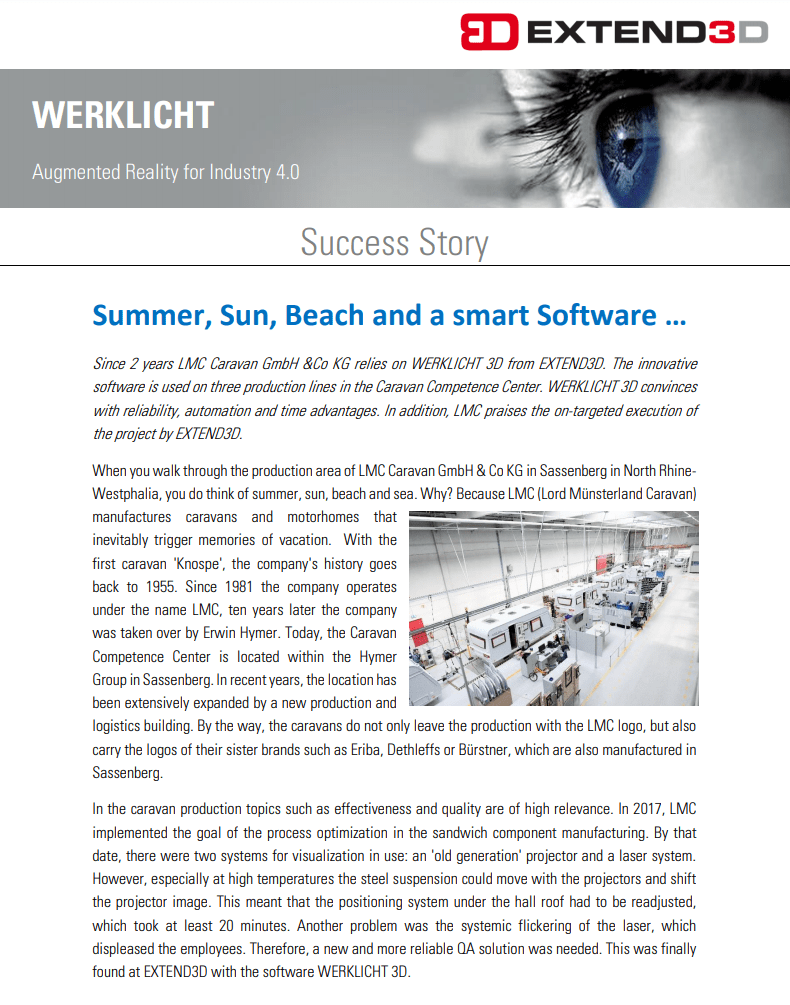

Since 2 years LMC Caravan GmbH &Co KG relies on WERKLICHT 3D from EXTEND3D. The innovative software is used on three production lines in the Caravan Competence Center…

Significantly increasing efficiency in bolt marking on the stationary measuring machine was the objec-tive of Audi‘s Technical Develop-ment department in car body con-struction approximately six years ago…

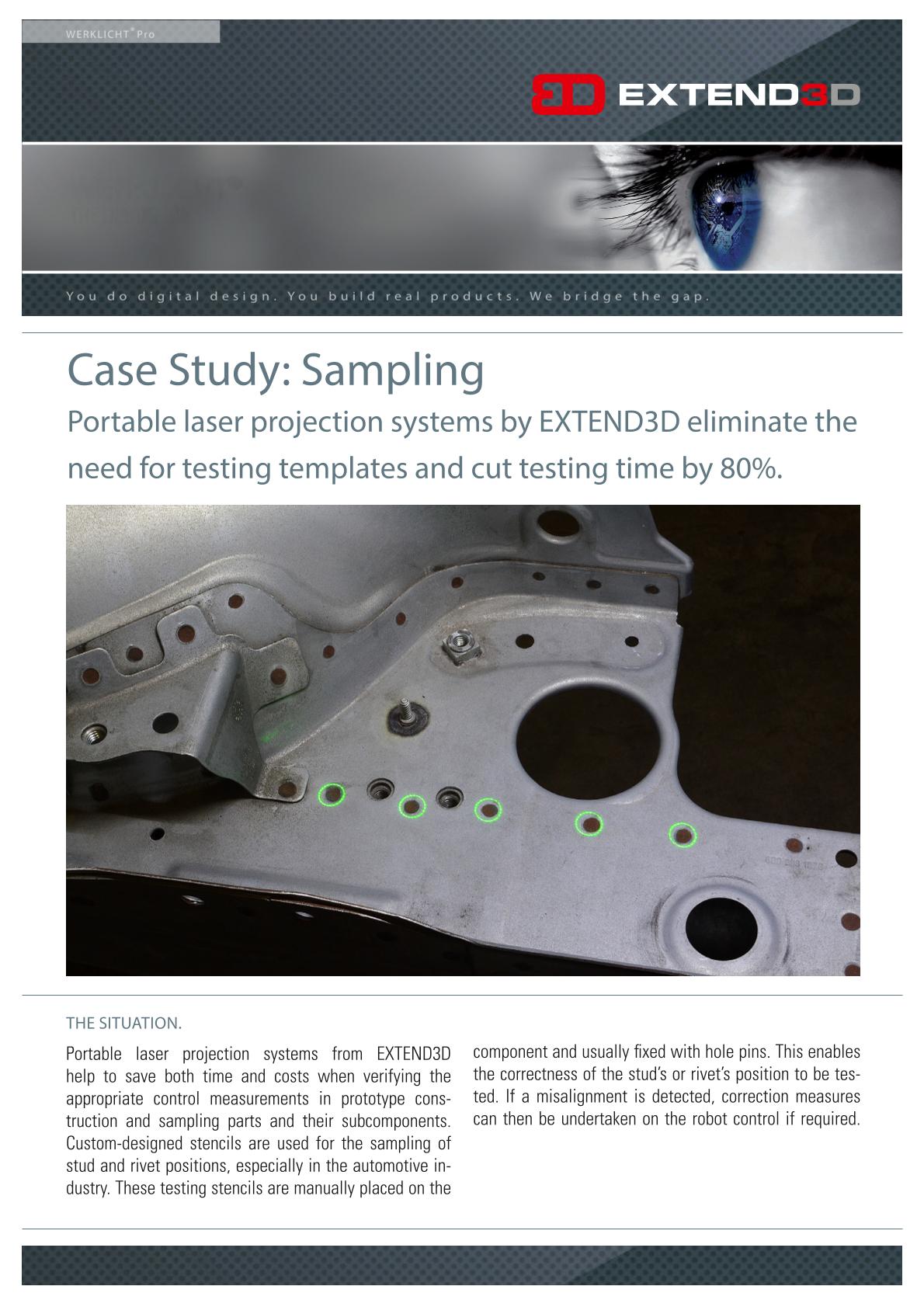

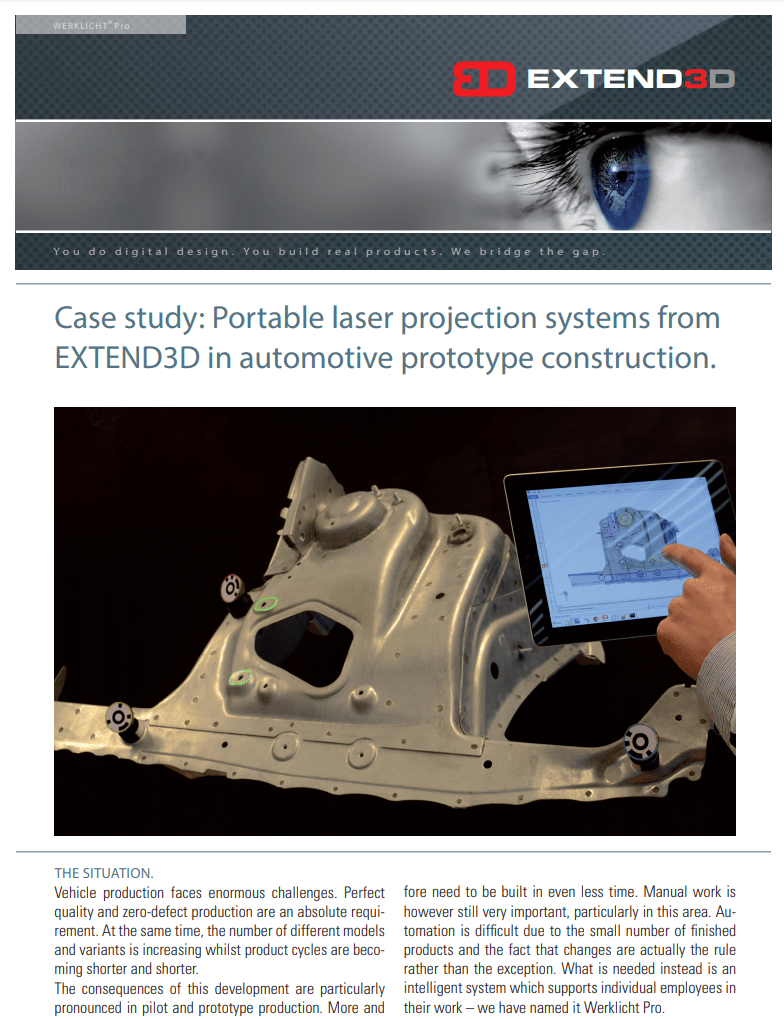

Portable laser projection systems from EXTEND3D help to save both time and costs when verifying the appropriate control measurements in prototype construction

and sampling parts and their subcomponents. Custom-designed stencils are used for the sampling of stud and rivet positions, especially in the automotive industry. …

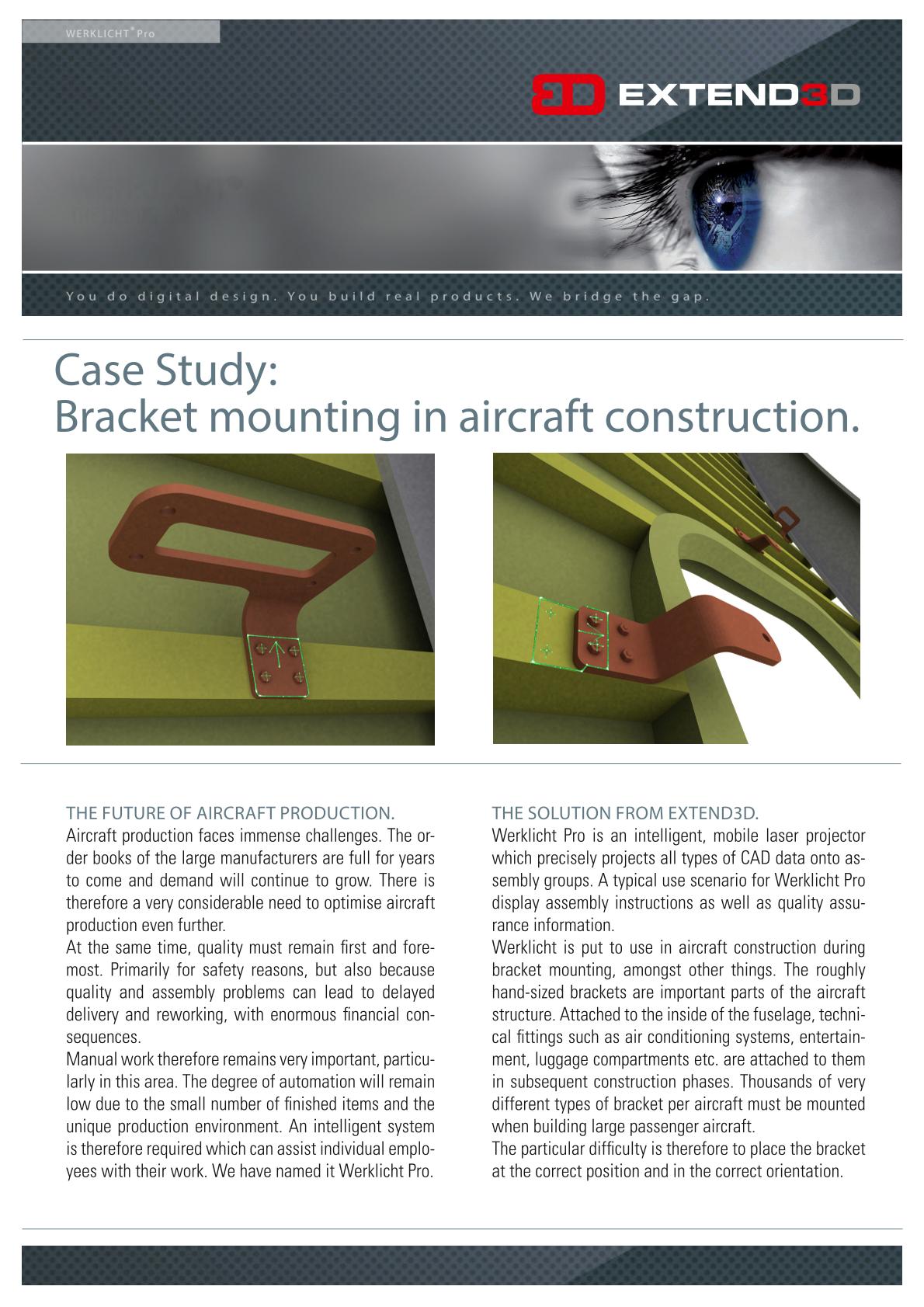

Aircraft production faces immense challenges. The order books of the large manufacturers are full for years to come and demand will continue to grow. There is therefore a very considerable need to optimise aircraft production even further.

At the same time, quality must remain first and foremost. …

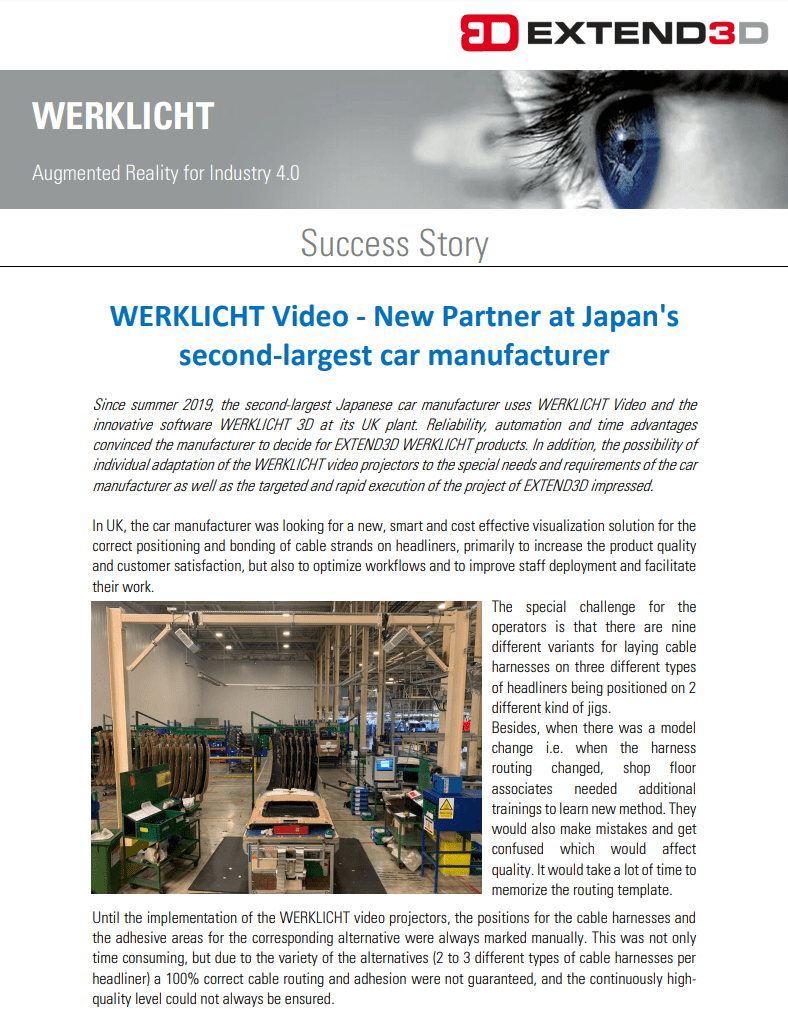

Since summer 2019, the second-largest Japanese car manufacturer uses WERKLICHT Video and the innovative software WERKLICHT 3D at its UK plant. Reliability, automation and time advantages convinced the manufacturer to decide for EXTEND3D WERKLICHT products…

Old hat in science fiction novels and films but excitingly new in the working world: Virtual Reality (VR) and Augmented Reality (AR) are now also gaining increasing foothold in industrial work processes…

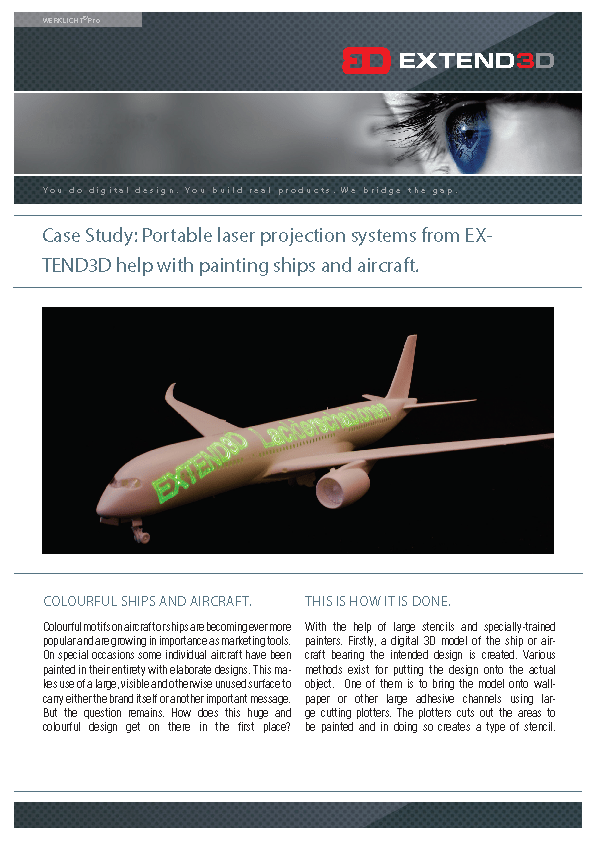

Colourful motifs on aircraft or ships are becoming ever more popular and are growing in importance as marketing tools. On special occasions some individual aircraft have been painted in their entirety with elaborate designs…

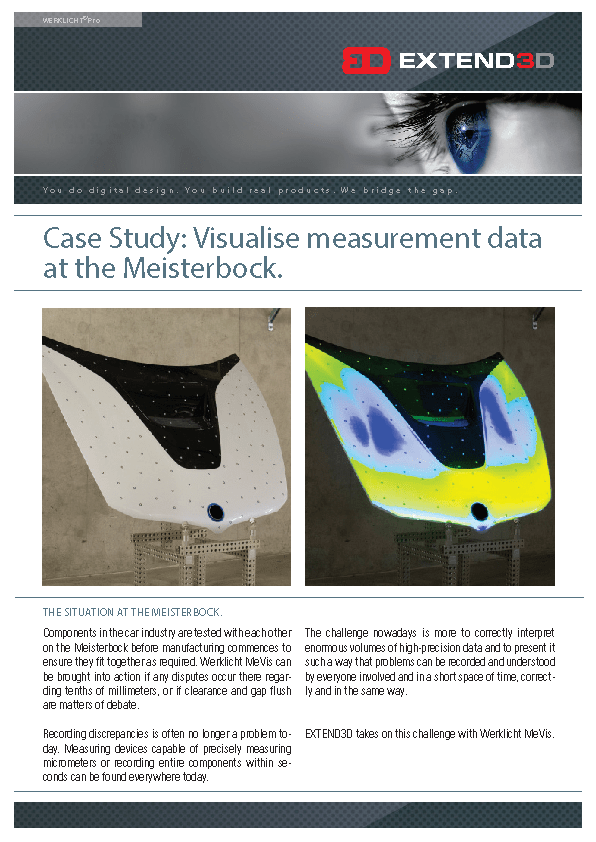

Components in the car industry are tested with each other on the Meisterbock before manufacturing commences to ensure they fit together as required…

Vehicle production faces enormous challenges. Perfect quality and zero-defect production are an absolute requirement. At the same time, the number of different models and variants is increasing whilst product cycles are beco-ming shorter and shorter…